Energetics

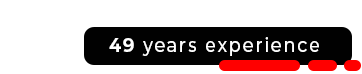

Steam turbine spare parts

Posteor ® supplies a wide range of spare parts for steam turbines made by various OEM, e.g. PBS, Skoda, Siemens, Alstom, Lang, Zamech, AEG, KKK, ABB, BBC, Yugoturbina.

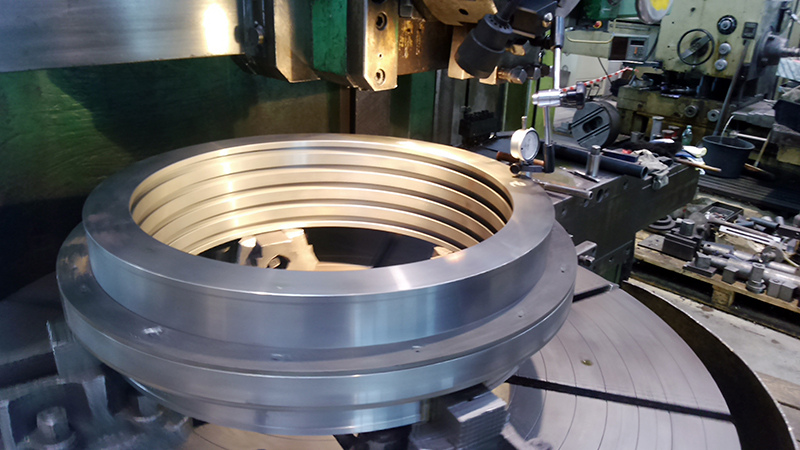

Production is carried out based on the entrusted documentation or documentation made by our team according to the principles of reverse-engineering.

As a result of the project co-financed by European Funds, entitled “Implementation of the technology of manufacturing spare parts for steam turbines using the reverse-engineering method”, posteor ® has implemented a new manufacturing process of spare parts for steam turbines.

The previously using process has been improved and modernized. Introduced changes allow for a shorter manufacturing time, bigger precision of workmanship and greater durability of the elements by increasing the hardness in the nitriding process.

Changes concern key steps of the manufacturing process of spare parts i.e. measurements, stellite surfacing and surface preparation for gas nitriding.

Our offer includes the production of spare parts for steam turbines and auxiliary devices:

- steering diaphragms (discs)

- nozzle segments

- complete stop valves,

- complete control valves,

- complete stop valves servomotors,

- complete control valves servomotors,

- diffusers,

- valve spindles,

- labyrinth bushings,

- guide bushings,

- valve heads,

- valve initial heads,

- sealing rings,

- labyrinth seals,

- diaphragm gland bodies,

- hull and valve bolts,

- bearings,

- couplings,

- gear wheels and rims,

- cams,

- worm gear parts

Renovations of steam turbines

Posteor ® offers a comprehensive renovation service taking into account maintaining the operational availability, reduction of number and time of downtime and optimalization of operating costs.

The scope of our services is tailored individually to the client’s needs and mainly concerns repairs:

- complete turbine sets

- torque converter

- condensate pumps

- backflow preventer

- heat exchangers,

- fittings,

- bearing stands,

- steering disk clamps,

- gland bodies,

- valve chambers,

- turbine bearings,

- nozzle boxes,

- control systems,

- lubricating and jacking oil systems,

- rotor clutches,

- improvement of structural nodes during renovation activities

Diagnostics services

Information about the turbine status and turbine related devices is collected as part of the diagnostic study.

The collected information allows to assess the changes taking place in the turbine operation and plan activities related to the improvement on the operation of the devices.

If required we offer our assistance in configuring the optimal scope of diagnostics.

The scope of diagnostic service is tailored individually to the client’s needs and applies to:

- diagnostics of control systems,

- diagnostics of lubricating oil systems,

- diagnostics of the dynamic state on the machine,

- modernization of special measurement systems.

The main elements of the turbine regulation systems are renovated in our workshop and tested at our hydraulic testing station.

We perform diagnostics of both modern electro-hydraulic solutions based on medium and high pressure systems and actuators from Vickers, Rexroth, Moog, Voith, as well as conventional low and medium pressure mechanical-hydraulic systems. Our equipment allows for the diagnosis and setting of the following assemblies.

Diagnostics is provided for the following units:

- control valve servomotors,

- stop valve servomotors,

- mechanical safety regulators,

- mechanical rotation regulators,

- pressure regulators,

Modernization

Modernization of turbine sets is aimed at increasing their efficiency, preventing excessive wear of devices and improving overall efficiency, availability and ease of use.

By using of modern control and measurement devices, modernization reduces the costs on operation and repairs and enable early detection of possible faults.

The scope of modernization is tailored individually to the client’s needs and applies to:

- comprehensive modernization of turbine sets,

- comprehensive modernization of torque converters,

- lubricating systems,

- accelerated cooling systems,

- control systems,

- bypass systems,

- sealing systems,

- drainage systems,

- shut-off and control valves,

- jacking oil systems,

- oil vapor suction systems,

- backflow preventer systems

Production

We produce the following auxiliary equipment for steam turbines:

- steam condensers from glands,

- gland steam coolers,

- separation rings,

- lubricating oil coolers,

- gears,

- steam and water valves,

- overflow valves for lubricating and control oil,

- servomotors of control and shut-off valves

- hydraulic power units,

- main oil pumps,

- French flaps,

- KOS actuators,

Design and consulting

We provide design and consulting services in the scope of existing steam turbines and turbine-related systems. By using modern solutions for energy devices, we propose new and improved solutions which eliminate the weak points of old devices.

We offer consulting and design in the following areas:

- calculations of flow systems

- thermal calculations

- technical consultancy in the field of steam turbines

- strength calculations

- modernizations

- technical documentation done based on reverse engineering rules,

- analysis of the operation on turbines together with modernization recommendations

- economic and technical analysis serving as the basis of the Technical Terms for the repair of steam turbines,

- designing steam systems,

- designing cooling water systems,

- designing oil systems,

- foundation analysis

Automatic control systems

We offer a comprehensive service of electrohydraulic control systems i.e. design, production, assembly, commissioning, supervision in the scope of:

- electro-hydraulic turbine control systems,

- electrohydraulic torque converter control systems,

- machine automation systems,

- visualization, data acquisition,

- movement limiter systems.