Regulation systems and power hydraulics

Spare parts for hydraulic systems

Posteor ® supplies a wide range of spare parts for hydraulic systems. Production is carried out on the basis of both, entrusted customer’s technical documentation, or technical documentation done based on reverse engineering rules by posteor ® engineering team.

posteor ® may manufacture parts for both, modern high-pressure systems operating on non-flammable fluids based on electro-hydraulics, and for traditional low-pressure mechanical-hydraulic systems operating on turbine oils.

The offer includes the production of spare parts for:

- main oil pumps,

- oil coolers,

- overflow valves,

- shut-off valve servomotors,

- control valve servomotors,

- safety regulators,

- back pressure and technological steam extraction regulators,

- regulation sliders,

- turbine trip blocks,

- runoff enhancers,

Renovations of hydraulic systems

posteor ® offers a comprehensive repair service while maintaining the operational availability of the renovated device, reduction of number and time of downtime and optimalization of operating costs.

The scope of our services is tailored individually to the client’s needs and mainly concerns repairs:

- torque converter

- non-return flap actuators

- control systems,

- lubricating and jacking oil systems,

- main lubricating oil pump,

- oil coolers,

- overflow valves,

- shut-off valve servomotors,

- control valve servomotors,

- back pressure and technological steam extraction regulators,

- regulation sliders,

- turbine trip blocks,

- runoff enhancers,

- improvement of structural nodes during renovation activities,

Diagnostics

Information about the turbine status and turbine related devices is collected as part of the diagnostic study. The collected information allows to assess the changes taking place in the turbine operation and plan activities related to the improvement of the operation of the devices.

If required we offer our assistance in configuring the optimal scope of diagnostics.

The scope of diagnostic service is tailored individually to the client’s needs and applies to:

- diagnostics of control systems,

- diagnostics of lubricating oil systems,

- diagnostics of jacking oil systems,

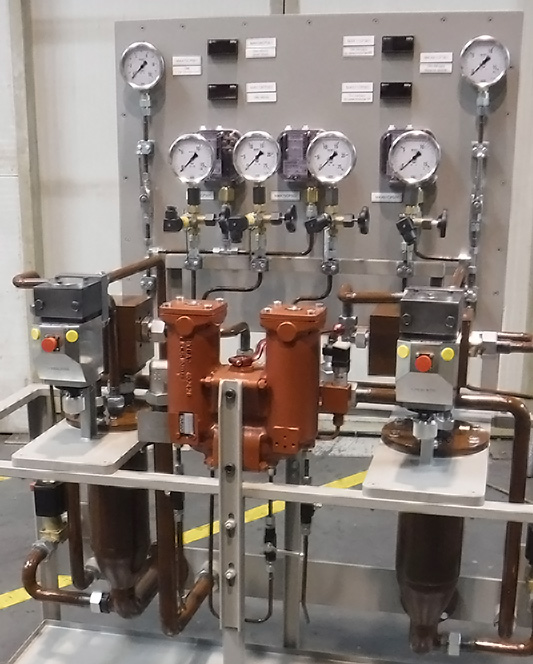

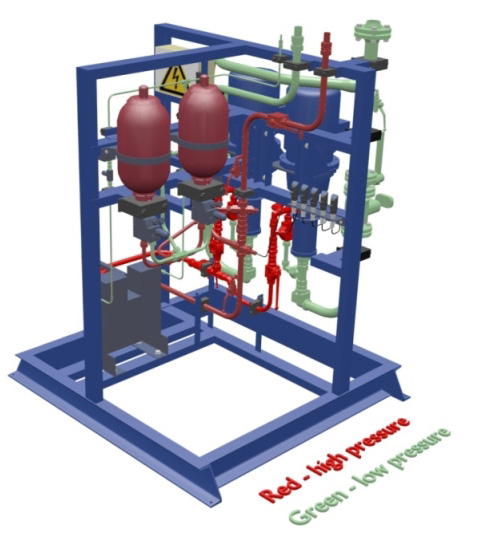

The main elements of the turbine regulation systems are renovated in our workshop and tested at our hydraulic testing station.

Diagnostics services may be provided for both: modern actuators (Vickers, Rexroth, Moog, Voith) which based or medium and high pressure electro-hydraulic systems and conventional low and medium pressure mechanical-hydraulic systems.

Diagnostics is provided for the following units:

- control valve actuators,

- shut-off valve actuators,

- mechanical safety regulators,

- mechanical rotation regulators,

- pressure regulators,

Modernization

Modernization of the turbine regulation system is aimed at increasing turbo set efficiency, preventing excessive wear of devices and improving overall efficiency, availability and ease of use.

By using of modern control and measurement devices, modernization reduce the costs of operation and repairs and enable early detection of possible faults.

The scope of modernization is tailored individually to the client’s needs and applies to:

- comprehensive modernization of torque converters,

- lubricating systems,

- control systems,

- bypass systems,

- shut-off and control valve actuators,

- jacking oil systems,

- oil vapor suction systems,

- backflow preventer systems

Produkcja

We produce the following auxiliary equipment for steam turbines:

- lubricating oil coolers,

- gears,

- overflow valves for lubricating and control oil,

- servomotors of control and shut-off valves

- hydraulic power units,

- main oil pumps,

- French flaps,

- KOS actuators,

Design and consulting

We provide design and consulting services in the scope of existing steam turbines and turbine-related systems. By using modern solutions for energy devices, we propose new and improved solutions which eliminate the weak points of old devices.

We offer consulting and design in the following areas:

- balance calculations of oil systems

- technical consultancy in the field of steam turbine regulation systems

- modernizations

- technical documentation done based on reverse engineering rules,

- designing oil systems,

Automatic control systems

We offer a comprehensive service of electrohydraulic control systems i.e. design, production, assembly, commissioning, supervision in the scope of:

- electro-hydraulic turbine control systems

- electrohydraulic torque converter control systems

- machine automation systems

- visualization, data acquisition

- movement restrictions systems

Benefits for users obtained thanks to modernization projects:

- Quality of regulation improvement including:

- the ability to fully adapt the turbine regulation system to the current and future requirements in the scope of primary and secondary regulation of the unit,

- the possibility of a simple setting optimization

- increasing the sensitivity of the regulation system

- optimization of the start-up time,

- improvement of stability of regulation ,

- limiting the impact of human operating errors,

- Increasing the safety of the turbine set:

- redundancy of the main functions of the regulator,

- two / three-channel safeguard systems with the possibility of control during operation,

- additional independent protection systems against turnover increase,

- improvement of the operational reliability of bypass systems,

- Extending the functionality and possibilities of the regulation system including:

- automation of the process of increasing the rotation and power of the turbine during

- start-up,

- possibility of cooperation with regulation systems of other devices in the power unit,

- possibility to change the structure and parameters of the regulation systems,

- possibility of automatic synchronization the turbogenerator with the power grid,

- possibility of coordination with boiler regulation system.

- Increasing the lifetime of the power unit :

- possibility of precise and repeatable process of starting up and power increasing,

- monitoring of thermal stresses in the main elements of the turbine,

- limitation of accidental shutdowns,

- Reducing the cost of periodic maintenance and renovation,

- minimal wear of electronic systems during operation,

- reducing the number of hydraulic and pneumatic sets,

- increasing the periods between renovations,

- shortening the time of maintenance or repair of the regulation system,

- Increasing the comfort of operation:

- the ability to watch many parameters in the system,

- exclusion of incorrect operator decisions,

- simple and logically designed operator panel,